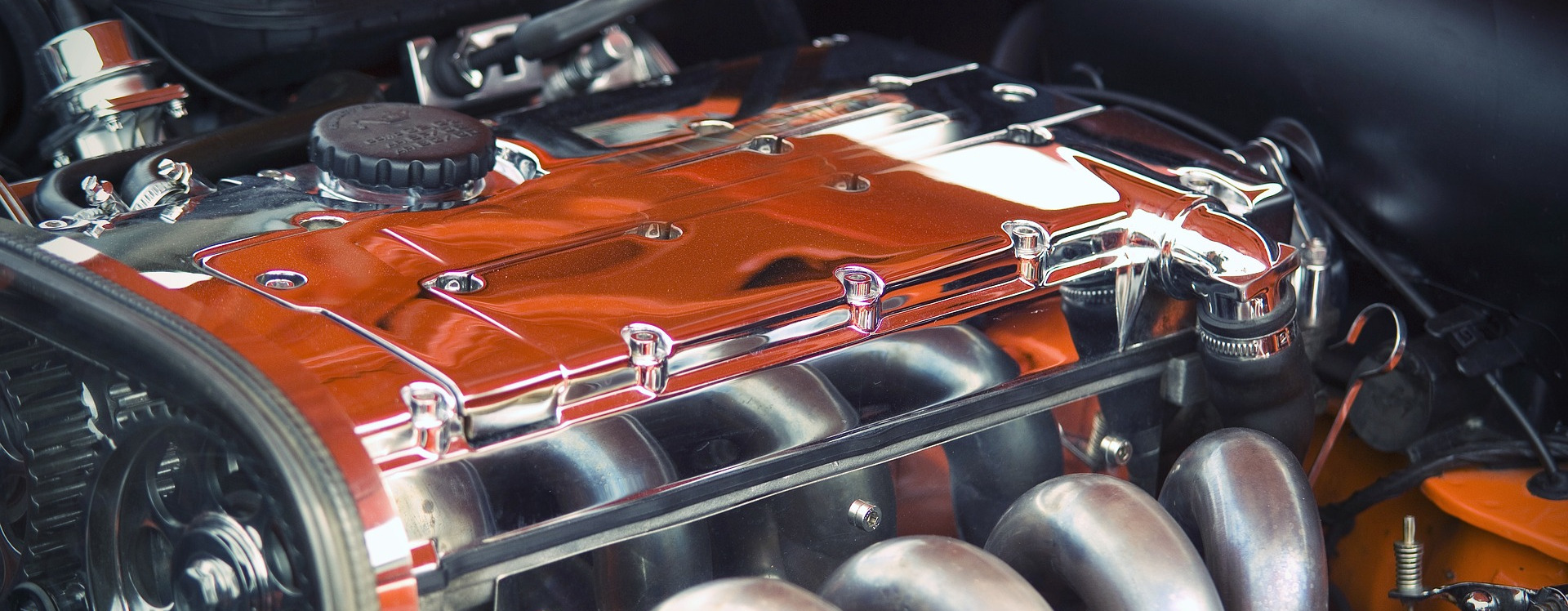

Funktionsweise des Tunings

Das Chiptuning funktioniert über eine Optimierung der Software im Motorsteuergerät. Hier werden verschiedene Parameter z.B. Treibstoffmenge, Zündzeitpunkt, Ladedruck etc. beeinflusst.

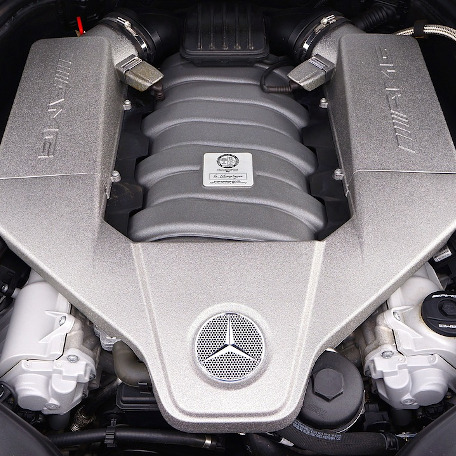

Grundsätzlich gibt es zwei Varianten des Tunings:

Den Einbau eines Chips (Zusatzmodul)

Die Optimierung der Software des Motorsteuergerätes

Beide Varianten basieren auf dem selben Prinzip. Die Steuerparameter, die den Zündzeitpunkt, die Luftzufuhr, die Treibstoffzufuhr etc. festlegen, werden innerhalb der Toleranzen, die vom Hersteller integriert sind, für die hiesigen Verhältnisse optimiert.

Die Fahrzeughersteller produzieren Ihre Fahrzeuge für den weltweiten Markt und stellen mit diesen Toleranzen sicher, dass das Fahrzeug in der Wüste genauso gut funktioniert wie in der sibirischen Kälte.

Durch das Tuning wird nur das Mögliche Ihres Motors genutzt, eine Gefährdung des Motors durch übertriebene Belastung ist nicht gegeben.

Ob ein Chip- oder Softwaretuning für Ihr Fahrzeug das richtige ist, hängt von Fahrzeug, Anforderung (zB. Verbrauchsoptimierung oder normales Tuning) ab.

Fragen Sie uns, unsere Stärke ist die individuelle Beratung, die zu einem optimalen Ergebnis führt!

Schicken Sie uns eine Fahrzeuganfrage , eine Email oder rufen Sie einfach an - wir beraten Sie gerne und vereinbaren einen Termin!